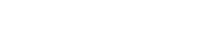

Understanding Valve Ball Design Types and Their Functions

Understanding Valve Ball Types and Functions

The design of a valve ball determines not only how flow is controlled but also the reliability, safety, and efficiency of the entire system. From general shut-off functions to complex multi-directional flow, different ball types are suited for specific applications. At BOLA-TEK, we manufacture not only standard valve ball designs but also specialize in producing custom OEM valve balls based on customer drawings and unique flow requirements—making us a true partner for global valve brands.

Introduction

Ball valves are essential components in flow control systems, and at the heart of every ball valve lies the valve ball itself. The internal structure and machining of the ball directly influence valve performance, pressure handling, sealing efficiency, and actuation torque. Choosing the right ball design is crucial for achieving the desired flow control function—be it isolation, diversion, mixing, or modulation.

BOLA-TEK offers a wide portfolio of OEM valve ball solutions, including floating, trunnion, solid, hollow, sealed cavity, and multiport balls. Our team also works closely with customers to develop custom-engineered ball designs for specialized valves and flow systems. Contact with BOLA-TEK now!

Overview of Ball Types

Floating Ball

- Best for: Low to medium pressure applications

- Advantage: Effective sealing by fluid pressure; simple and cost-efficient

- Applications: Water, air, oil, and gas pipelines

Trunnion Ball

- Best for: Large diameter or high-pressure valves

- Advantage: Reduced torque, increased stability, consistent sealing

- Applications: Oil & gas, petrochemical, heavy-duty systems

Solid Ball

- Strength: Withstands high pressure, temperature, and wear

- Usage: Demanding industrial environments requiring robust reliability

Hollow Ball

- Feature: Lighter internal structure

- Advantage: Reduces actuator torque and material cost

- Usage: General-purpose flow systems, large valves

Sealed Cavity Ball (Hollow Ball with Pipe)

- Function: Prevents pressure buildup from trapped media

- Usage: Volatile fluids, thermal expansion risk zones (chemical plants, petrochemicals)

Multiport Valve Ball Designs

L Port Ball (Diverter)

- Flow Path: 90° L-shape

- Function: Diverts flow from a common port to one of two outlets

- Applications: Sampling lines, switching between flow paths

- Feature: Precise flow direction control with quarter-turn operation

T Port Ball (Mixing/Splitter)

- Flow Path: T-shape interconnecting three ports

- Function: Mixes or splits flow; supports full flow through all three ports

- Applications: Fluid mixing, purging, constant flow systems

- Feature: Flexible—can also divert like an L-port when handle rotation is limited

X Port Ball (2×L-Port for 4-Way Valves)

- Flow Path: Two L-paths inside one ball

- Function: Manages dual isolated flows in one valve

- Applications: Loop switching, dual-line systems

- Feature: Space-saving design ideal for compact 4-way valves

F Port Ball (Custom Flow Design)

- Flow Path: Fully customized—hybrid or asymmetric drilling

- Function: Supports proprietary flow paths beyond standard patterns

- Applications: Specialized systems or OEM valves with unique flow demands

- Feature: Developed from customer drawings for tailored solutions

V Port Ball (Precision Flow Control)

- Design: V-shaped cut (15°, 30°, 45°, 60°, 90°, linear)

- Function: Provides linear or equal-percentage flow control

- Advantage: Accurate modulation as shaft rotates; maintains control at low and high flows

- Applications: Chemical dosing, paper mills, wastewater systems, throttling flow

- Feature: Balances high flow capacity with precise control, even under high velocity

BOLA-TEK: Your OEM Partner for Valve Balls

What sets BOLA-TEK apart is our ability to manufacture not only standard valve balls but also to collaborate on special OEM ball designs. With an in-house casting foundry, advanced machining shop, and decades of industry expertise, we support global valve manufacturers in turning their designs into reality.

- Custom designs based on client drawings

- Material options: Stainless steel, carbon steel, alloy steel, etc

Conclusion

Valve ball design isn’t one-size-fits-all. The right ball type can dramatically improve your system’s performance, reliability, and safety. Whether you're selecting a standard solution or developing a new flow control product, BOLA-TEK is your trusted partner for OEM valve balls built to perform—from Taiwan to the world.